-

1Light weight, high closed cell rate, excellent resilience and mechanical properties, both rigidity and flexibility, which is conducive to the replacement of lightweight requirements

-

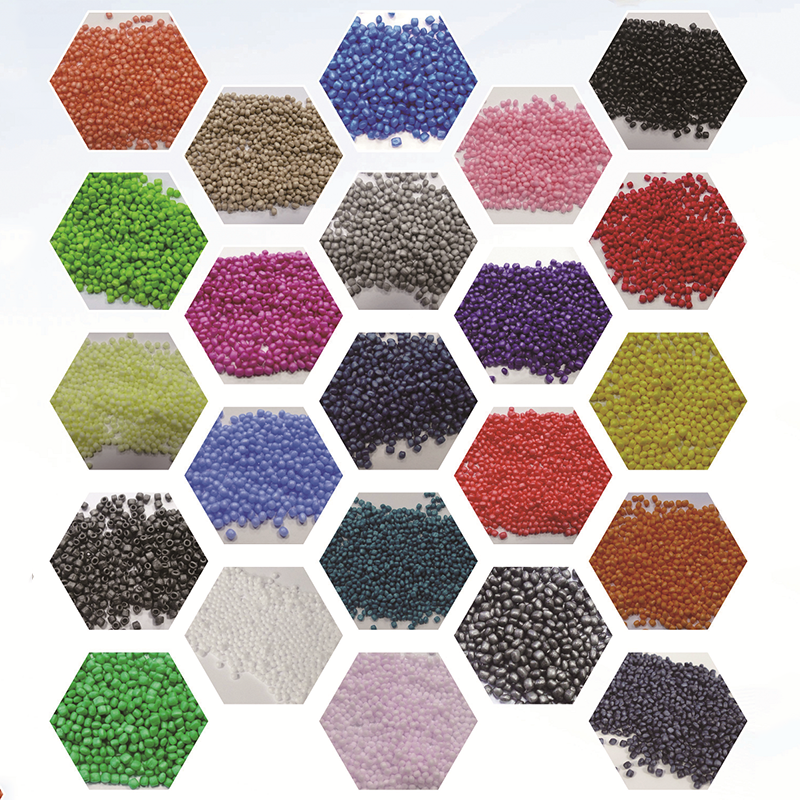

2The surface color of the molded parts is uniform, and the molding pressure and shrinkage rate are stable

-

3Low VOC, free of pentaphenyltrialdehyde-ketone substances, environmentally friendly, non-toxic and tasteless

-

tel: +86 189 0616 0161

-

email: yeming@wxhuitong.com.cn

ATMIS Normal EPP

ATMIS Normal EPP

Expanded Polypropylene (EPP) is a highly versatile closed-cell bead foam that provides a unique range of properties.

ATMIS-EPP can be made in a wide range of densities, from 15 to 200 g/l, which are transformed by moulding into densities ranging from 18 to 260 g/l. Individual beads are fused into final product form by the steamchest moulding process resulting in a strong and lightweight shape.

|

Physical properties |

TEST STANDARD |

UNIT |

20kg/m³±10% |

30kg/m³±10% |

40kg/m³±10% |

50kg/m³±10% |

|||||

|

Standards |

Result |

Standards |

Result |

Standards |

Result |

Standards |

Result |

||||

|

Density |

ISO 845 |

kg/m³ |

18-22 |

22 |

27-33 |

32.5 |

36-44 |

38 |

45-55 |

46.2 |

|

|

Tensile Strength |

ISO 1926 |

kPa |

>180 |

296 |

>240 |

451 |

>300 |

675 |

>400 |

571 |

|

|

Tensile Elongation |

% |

>12% |

16 |

>12% |

22 |

>10% |

14 |

>10% |

18 |

||

|

Compression Stress |

25% |

ISO 844 |

kPa |

≥14 |

82 |

≥66 |

185 |

≥142 |

301 |

≥215 |

343 |

|

50% |

>80 |

157 |

>120 |

232 |

>180 |

376 |

>300 |

399 |

|||

|

Compression Set |

ISO 1856-C |

% |

<35% |

26.23 |

<45% |

36.92 |

<45% |

37.25 |

<45% |

37.51 |

|

|

Flammability |

GB 8410 |

mm/min |

≤80 |

78.96 |

≤80 |

62.72 |

≤80 |

51.14 |

≤80 |

43.79 |

|

|

Physical properties |

TEST STANDARD |

UNIT |

60kg/m³±10% |

70kg/m³±10% |

80kg/m³±10% |

90kg/m³±10% |

|||||

|

Standards |

Result |

Standards |

Result |

Standards |

Result |

Standards |

Result |

||||

|

Density |

ISO 845 |

kg/m³ |

54-66 |

60.6 |

63-77 |

65.7 |

72-88 |

79.5 |

81-99 |

85.6 |

|

|

Tensile Strength |

ISO 1926 |

kPa |

>450 |

856 |

>500 |

961 |

>600 |

1124 |

>700 |

1210 |

|

|

Tensile Elongation |

% |

>10% |

25 |

>10% |

24 |

>10% |

24 |

>10% |

24 |

||

|

Compression Stress |

25% |

ISO 844 |

kPa |

≥295 |

450 |

≥381 |

488 |

≥473 |

591 |

≥572 |

636 |

|

50% |

>380 |

523 |

>450 |

567 |

>550 |

986 |

>650 |

1051 |

|||

|

Compression Set |

ISO 1856-C |

% |

<45% |

37.76 |

<45% |

37.98 |

<45% |

38.22 |

<45% |

38.41 |

|

|

Flammability |

GB 8410 |

mm/min |

≤80 |

40.32 |

≤80 |

39.28 |

≤80 |

37.54 |

≤80 |

36.2 |

|

|

Physical properties |

TEST STANDARD |

UNIT |

120kg/m³±10% |

150kg/m³±10% |

180kg/m³±10% |

200kg/m³±10% |

|||||

|

Standards |

Result |

Standards |

Result |

Standards |

Result |

Standards |

Result |

||||

|

Density |

ISO 845 |

kg/m³ |

108-132 |

112.8 |

135-165 |

142.37 |

162-198 |

165.28 |

180-220 |

183.54 |

|

|

Tensile Strength |

ISO 1926 |

kPa |

>900 |

1328 |

>950 |

1691 |

>1000 |

2064 |

>1100 |

2282 |

|

|

Tensile Elongation |

% |

>8% |

28 |

>8% |

19 |

>5% |

20 |

>5% |

21 |

||

|

Compression Stress |

25% |

ISO 844 |

kPa |

/ |

838 |

/ |

1158 |

/ |

1344 |

/ |

1492 |

|

50% |

>1000 |

1221 |

>1500 |

1808 |

>2100 |

2355 |

>2500 |

2773 |

|||

|

Compression Set |

ISO 1856-C |

% |

<45% |

38.87 |

<45% |

39.01 |

<45% |

39.23 |

<45% |

39.56 |

|

|

Flammability |

GB 8410 |

mm/min |

≤80 |

34.09 |

≤80 |

30.66 |

≤80 |

29.48 |

≤80 |

27.26 |

|