-

tel: +86 189 0616 0161

-

email: yeming@wxhuitong.com.cn

HTEC shoulders the responsibility of the times bravely and builds a recyclable foam product system

HTEC shoulders the responsibility of the times bravely and builds a recyclable foam product system

HTEC, as the pioneer of China's EPP industry, combines the upstream and downstream industries (equipment, raw materials, molding, branding, etc.), from the perspective of sustainable development, actively explores the three aspects of recycling, regeneration, and utilization to solve EPP The industry problem of difficult recycling of waste products forms a circular system of the entire EPP industry chain, realizes the sustainable utilization of resources, and helps the realization of the goal of carbon neutrality!

|

Recycling status |

Why is recycling difficult? |

Plan |

|

EPP raw material side, molding side:

Brand user:

centralized recycling point: |

The market is small and scattered |

HTEC EPP has a high market share, and the factory layout is perfect, which can realize multiple points and nearby recycling |

|

The special-shaped structure makes the volume larger and the cost of recycling and transportation is high |

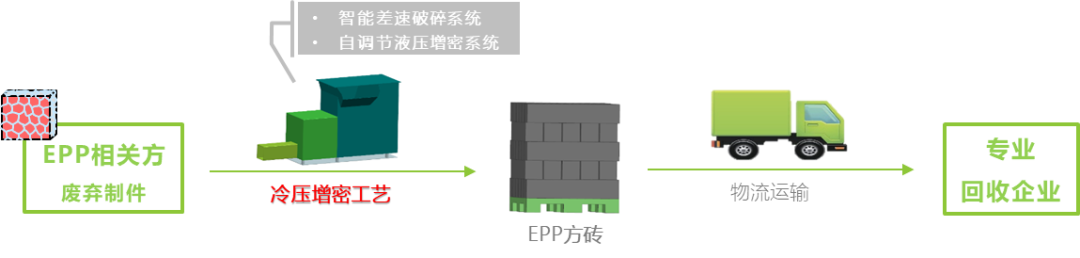

HTEC self-developed cold-pressing densification equipment can compress the volume to more than 1/30 of the original volume at the recycling site, reducing logistics costs |

|

|

The technical barriers to recycling are high, and the recycling value is low |

1. Through Huitong's unique patented technology, the comprehensive performance of recycled PP particles is improved by more than 50% compared with traditional recycling processes; |

So, how to realize the recycling system of EPP?

EPP waste parts can be compressed to more than 1/30 of the volume of EPP special-shaped waste parts through special cold-pressing densification equipment, that is, EPP square bricks;

After the EPP square brick is compressed in volume, it can greatly reduce the cost of recycling logistics;

Regular EPP square bricks can be transported to recycling companies with professional recycling qualifications through logistics for recycling.

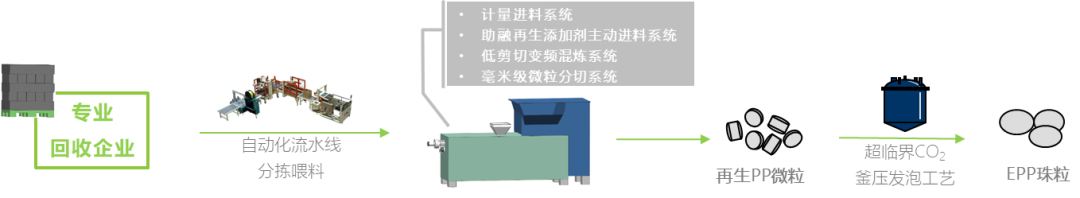

Professional recycling companies transfer square bricks through automated assembly lines, and directly enter the feeding system of EPP special hot-melt recycling equipment;

The regenerated PP particles prepared by the cold press densification process and the EPP special hot melt regeneration process have mechanical properties improved by more than 50% compared with the traditional melt granulation process, and the melt strength is restored to more than 90%. It is suitable for supercritical carbon dioxide of EPP Kettle pressure foaming process;

Due to its excellent performance, recycled PP particles can also be mixed into PP modified particles in a large proportion for plastic processing such as injection molding, blister molding, and extrusion molding.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.png?x-oss-process=image/resize,w_100/quality,q_100)